Very often small and medium companies do not benefit of all the advantages that could be achieved through the use of virtual simulation and optimization techniques in the design chain.

We briefly expose the three main reasons which, according to our experience, determine this situation.

They can be substantially due to a mistrust towards the virtual prototyping as an effective way to improve and grow, the wrong trust that enormous hardware facilities are needed and the high cost of software licenses.

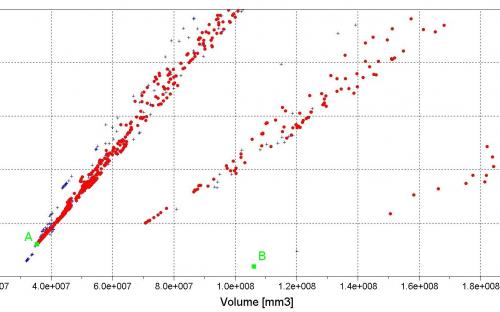

Many words could be spent discussing the first issue: however, in this paper we prefer to focus our attention on the second two points, showing that a constrained multiobjective optimization problem involving an industrial real problem can be solved using Scilab and other open source software with reduced hardware facilities.

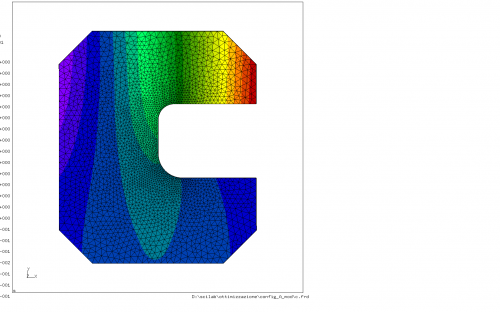

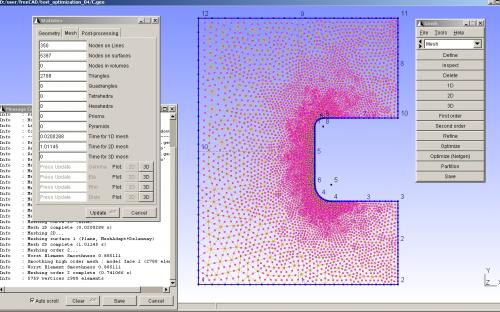

We show that Scilab can be used as a PIDO (Process Integration and Design Optimization) tool: we integrate two different open source software (gmsh and CalculiX) to manage a parametric geometry, mesh and solve a structural model and we finally drive the search toward optimal configurations using a genetic algorithm.

The obtained results are really impressive: we let the reader to understand how much money can be saved with this design approach.

| Attachment | Size |

|---|---|

| 1.4 MB |